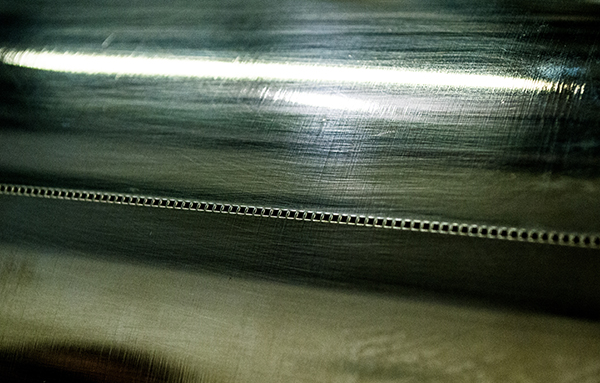

ROTHTEC® uses electroforming to produce custom seamless nickel sleeves and screens that are used in a variety of industries. In the electroforming process the nickel sleeves and screens are “grown” by electrodeposition on a mandrel. Electroforming of rotary printing screens is the largest single application of nickel electroforming, according to the Nickel Institute, which is why electroforming fits so well with ROTHTEC®’s original core business of engraving rotary screens for the textile industry.

The Nickel Institute describes electroforming as follows. “Electroforming is an electrodeposition process, similar to electroplating and electrorefining. Therefore, the process requires two electrodes (an anode and a cathode) immersed in a conducting electrolyte containing metallic salts and a source of DC power. As current is passed between the two electrodes, metallic ions in solution e.g. Ni++, are converted into atoms on the cathode surface and these build up layer upon layer, micron upon micron to produce a continuous deposit.”

More detailed information is available on these pages for each of these ROTHTEC® electroformed products. We would be happy to work with you to customize an electroformed nickel product that is perfect for your use.

- Air Embossing Sleeves

- Flexographic Sleeves

- Laminating Screens and Coating Screens

- Nickel Shims

- Nickel Sleeves and Nickel Screens

Electroformed Nickel Product Specifications

All of ROTHTEC®’s electroformed products, are available in:

- Lengths of: 153 mm to 2438 mm, and some products up to 3500

- Diameters of: 438 mm to 1436 mm, and soon to be 2075 mm

- Thicknesses of: 76 microns to 558 microns, soon to be 660 microns